Ukuthengiswa okuqondileko kwefektri

Sizokwenza yoke imizamo yokuthi sibe ngabantu abahle begodu baphelele, begodu sirhabise amagadango wethu wokuma esikhundleni samabhizinisi wezinga eliphezulu nethekhnoloji ephezulu yamazwe ngamazwe wokuThenga okukhulu kwe-ANSI Casting Dual-PlateI-Wafer Check Valve I-Valve yokuhlola amapuleti amabili, Samukela amaklayenti amatjha nasele aphelelwe sikhathi ukuthi athintane nathi ngomakhalekhukhwini nofana asithumelele imibuzo ngeposi malungana nobudlelwano bebhizinisi besikhathi eside nokufeza imiphumela efanako.

Sizokwenza yoke imizamo yokuthi sibe ngabantu abahle begodu baphelele, begodu sirhabise amagadango wethu wokujama esikhundleni samabhizinisi wezinga eliphezulu nethekhnoloji ephezulu weentjhabatjhabaUmhlobo we-Wafer Check Valve, Siyakwamukela ukuvakatjhela ikhamphani yethu, ifemu kanye negumbi lethu lokutjengisa lapho kuvezwa khona iinsombululo ezihlukahlukeneko zeenhluthu ezizokuhlangabezana nokulindelweko kwakho. Khatheso, kulula ukuvakatjhela iwebhusayithi yethu, begodu abasebenzi bethu bokuthengisa bazokuzama ngamandlabo woke ukukunikela isevisi engcono khulu. Qiniseka bona uyasithinta nangabe ufuna ilwazi elinabileko. Umnqopho wethu kukusiza amakhasimende bona afeze imigomo yawo. Senza imizamo emikhulu ukufikelela ubujamo bokuphumelela.

Ihlathululo:

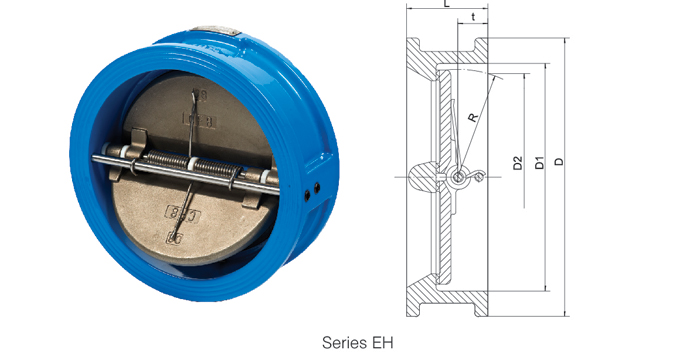

I-EH Series Dual plate waferivalvu yokuhlola ineenthoro ezimbili ezifakwe kiwo woke amapuleti wamavalvu, avala amapuleti msinyana begodu ngokuzenzakalelako, okungakhandela bona umtjhini ungabuyeli emuva.Ivalvu yokuhlola ingafakwa emapayipini avundlileko najameleko.

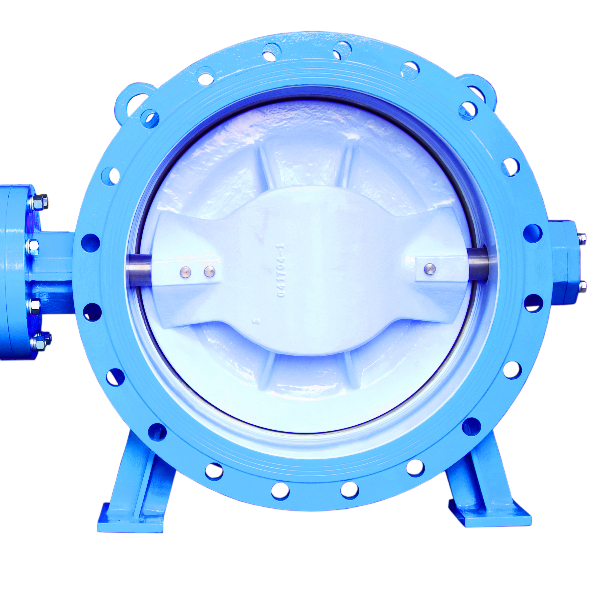

Enye yezinto eziqakathekileko zethuamavalvu wokuhlola i-waferyindlela yabo yamapuleti amabili. Idizayini ehlukileko le yenza bona kube nokwakhiwa okuncani, okulula lokha nakunikelwa ukulawula okuphezulu kokugeleza. Amapuleti amabili asebenza ndawonye ukwenza isivalo esiqinileko, ukukhandela nanyana ngikuphi ukugeleza emuva nofana ukuvuza. Isici lesi senza i-valve yethu yokuhlola enepuleti ezimbili ibe yihle emabubulweni anesikhala esincani ngombana ingafakwa ngokuvundlileko nofana ngokujameleko.

Phezu kwalokho, amavalvu wethu wokuhlola afakwe iintulo zerabha ukuthuthukisa amandla wokuvala. Amavalvu wokuhlola ahlelwe ngerabha anikela ukuvala okuqinileko kwamanzi namagesi, ukuqinisekisa ukulawulwa kokugeleza okuphephileko nokukhandela nanyana ngikuphi ukuvuza okungenzeka. Isici lesi sibuye sinikele ngokujamelana nokugqwala okuhle khulu, okwenza bona amavalvu wethu wokuhlola alungele ukusetjenziswa eendaweni ezihlukahlukeneko.

Amavalvu wokuhlola ngamavalvu womhlobo we-wafer aziwa ngokuba lula nokulula ukuwafakwa. Amavalvu wokuhlola ama-wafer aklanyelwe ukulingana hlangana nama-flange amabili ngaphandle kokuhlanganisa okungezelelweko nofana i-hardware. Umklamo lo awunciphisi isikhathi sokufaka neendleko kwaphela, kodwana uvumela ukususwa lula nofana ukutlhogomela lokha nakutlhogekako.

Ipuleti eliphindwe kabiliamavalvu wokuhlola we-wafer ahlezi ngerabhazisisombululo sezinga lokuthoma lokulawula ukugeleza nokukhandela ukugeleza emuva eenhlelweni ezihlukahlukeneko. Ubukhulu bayo obuncani, amandla wokuvala athembekileko nobulula bokufaka kwenza bona ibe yisengezo esihle kiwo woke amabubulo. Tjala imali emavalvu wethu wokuhlola namhlanjesi begodu uzizwe iinzuzo zokulawula ukugeleza okusebenzako nokuphephileko.

Ubunjalo:

-Incani ngobukhulu, ilula ngobunzima, incani ngokwesakhiwo, kulula ukuyitlhogomela.

-Kufakwa ama-torsion spring amabili kiwo woke amapuleti we-valve, avala amapuleti msinya begodu ngokuzenzakalelako.

-Isenzo setjhila elirhabako sivimbela umphakathi bona ungagelezeli emuva.

-Mfitjhani ubuso nobuso nokuqina okuhle.

-Kulula ukufakwa, ingafakwa emapayipini avundlileko nalawo aqondileko.

-Ivalvu le ivalwe kuhle, ngaphandle kokuvuza ngaphasi kokuhlolwa komfutho wamanzi.

-Iphephile begodu ithembekile ekusebenzeni, ukujamelana nokuphazamiseka okuphezulu.

Iimbawo:

Ukusetjenziswa okujayelekileko emabubulweni.

Ubukhulu:

| Isayizi | D | D1 | D2 | L | R | t | Ubunzima (kg) | |

| (mm) | (intjhi) | |||||||

| 40 | 1.5′′ | 92 | 65 | 43.3 | 43 | 28.8 | 19 | 1.5 |

| 50 | 2′′ | 107 | 65 | 43.3 | 43 | 28.8 | 19 | 1.5 |

| 65 | 2.5′′ | 127 | 80 | 60.2 | 46 | 36.1 | 20 | 2.4 |

| 80 | 3′′ | 142 | 94 | 66.4 | 64 | 43.4 | 28 | 3.6 |

| 100 | 4′′ | 162 | 117 | 90.8 | 64 | 52.8 | 27 | 5.7 |

| 125 | 5′′ | 192 | 145 | 116.9 | 70 | 65.7 | 30 | 7.3 |

| 150 | 6′′ | 218 | 170 | 144.6 | 76 | 78.6 | 31 | 9 |

| 200 | 8′′ | 273 | 224 | 198.2 | 89 | 104.4 | 33 | 17 |

| 250 | 10′′ | 328 | 265 | 233.7 | 114 | 127 | 50 | 26 |

| 300 | 12′′ | 378 | 310 | 283.9 | 114 | 148.3 | 43 | 42 |

| 350 | 14′′ | 438 | 360 | 332.9 | 127 | 172.4 | 45 | 55 |

| 400 | 16′′ | 489 | 410 | 381 | 140 | 197.4 | 52 | 75 |

| 450 | 18′′ | 539 | 450 | 419.9 | 152 | 217.8 | 58 | 101 |

| 500 | 20′′ | 594 | 505 | 467.8 | 152 | 241 | 58 | 111 |

| 600 | 24′′ | 690 | 624 | 572.6 | 178 | 295.4 | 73 | 172 |

| 700 | 28′′ | 800 | 720 | 680 | 229 | 354 | 98 | 219 |

Sizokwenza yoke imizamo yokuthi sibe ngabantu abahle begodu baphelele, begodu sirhabise amagadango wethu wokuma esikhundleni samabhizinisi wezinga eliphezulu nethekhnoloji ephezulu yamazwe ngamazwe wokuThenga okukhulu kwe-ANSI Casting Dual-PlateI-Wafer Check Valve I-Valve yokuhlola amapuleti amabili, Samukela amaklayenti amatjha nasele aphelelwe sikhathi ukuthi athintane nathi ngomakhalekhukhwini nofana asithumelele imibuzo ngeposi malungana nobudlelwano bebhizinisi besikhathi eside nokufeza imiphumela efanako.

Ukuthenga okukhulu kwama-Valve we-China kanye ne-Check Valve, Siyakwamukela ukuvakatjhela ikhamphani yethu, ifemu kanye negumbi lethu lokutjengisa lapho kutjengisa khona iinsombululo ezihlukahlukeneko zeenwele ezizokuhlangabezana nokulindelweko kwakho. Khatheso, kulula ukuvakatjhela iwebhusayithi yethu, begodu abasebenzi bethu bokuthengisa bazokuzama ngamandlabo woke ukukunikela isevisi engcono khulu. Qiniseka bona uyasithinta nangabe ufuna ilwazi elinabileko. Umnqopho wethu kukusiza amakhasimende bona afeze imigomo yawo. Senza imizamo emikhulu ukufikelela ubujamo bokuphumelela.