1. Ukuhlaziywa kwesakhiwo

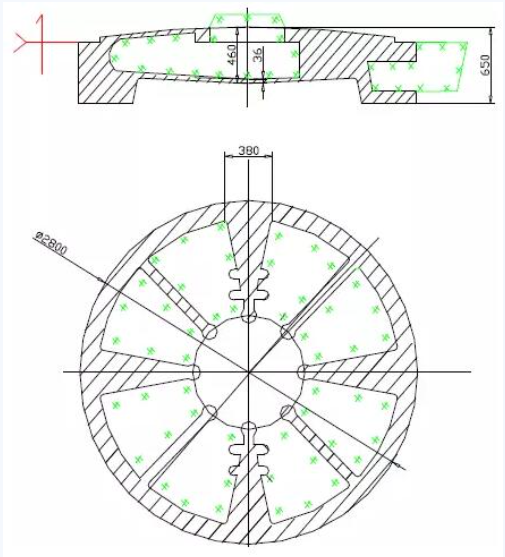

(1) Lokhuivalvu yevivaneinesakhiwo esiyindilinga esibunjwe njengekhekhe, umgodi wangaphakathi uhlanganiswe begodu usekelwa ziimbambo eziqinisako ezi-8, umgodi ongaphezulu we-Φ620 ukhulumisana nomgodi wangaphakathi, begodu koke okuselekoivalvuivaliwe, umgogodla wesihlabathi kubudisi ukuwulungisa begodu kulula ukuwohloka. Kokubili ukukhipha ummoya nokuhlanza umgodi wangaphakathi kuletha ubudisi obukhulu, njengombana kutjengiswe kuMfanekiso 1.

Ubukhulu bodonga lweenthombe buyahluka khulu, ubukhulu obuphezulu bodonga bufinyelela ku-380mm, begodu ubuncani bodonga bufika ku-36mm kwaphela. Lokha ukuphoswa nakuqinileko, umehluko wezinga lokutjhisa mkhulu, begodu ukuncipha okungalingani kungakhiqiza lula imigodi yokuncipha kanye nokukhubazeka kokuncipha, okuzokwenza bona amanzi ageleze ekuhlolweni kwe-hydraulic.

2. Umklamo wenqubo:

(1) Indawo yokuhlukanisa itjengiswa emfanekisweni 1. Faka isiphetho esinemigodi ebhokisini elingaphezulu, yenza umgogodla wesihlabathi woke emgodini ophakathi, bese ukhulisa ihloko yomgogodla ngendlela efaneleko ukusiza ukubophelela komgogodla wesihlabathi nokunyakaza komgogodla wesihlabathi lokha ibhokisi naliphendulwako. Ukuzinza, ubude behloko ye-cantilever core yemigodi emibili engabonakaliko ehlangothini bude ukudlula ubude bomgodi, ukwenzela bona isikhungo se-gravity yomgogodla wesihlabathi woke sithambekele ehlangothini lekhanda lesihlabathi ukuqinisekisa bona umgogodla wesihlabathi umile begodu uzinzile.

Irherho lokuthulula elivaliweko liyamukelwa, ∑F ngaphakathi: ∑F elivundlileko: ∑F liqondile=1:1.5:1.3, i-sprue isebenzisa itjhubhu ye-ceramic enobubanzi bangaphakathi obungu-Φ120, begodu iinquntu ezimbili zezitina eziqinileko ezingu-200×100×40mm zibekwa phasi ukukhandela ukutjhayisana ngqo ngensimbi isikhunta sesihlabathi, isihlungi se-150×150×40 se-foam seramikhi sifakwe ngaphasi kwe-runner, begodu amashubhu we-ceramic ali-12 anobubanzi bangaphakathi obungu-Φ30 asetjenziselwa i-runner yangaphakathi ukuxhuma ngokulinganako nephasi lokuphosa ngethangi lokubuthelela amanzi ngaphasi kwe-filter ukwakha ukuthulula okuphasi njengombana kutjengiswe emfanekisweni 2

(3) Faka iimbobo zomoya eziyi-14 ∮20 emgodini ongaphezulu, faka umgodi wokukhipha umoya we-Φ200 phakathi kwehloko yomgogodla, faka insimbi ebandako eencenyeni eziqinileko nezikulu ukuqinisekisa ukuqina okulinganiselweko kokufakwa, begodu usebenzise umthetho wokunwebeka kwe-graphitization ukukhansela Ikambiso yokudla esetjenziselwa ukwenza ngcono isivuno. Ubukhulu bebhokisi lesihlabathi buyi-3600×3600×1000/600mm, begodu ihlanganiswe ngepuleti lensimbi elingama-25mm ukuqinisekisa ukuqina okwaneleko nokuqina, njengombana kutjengiswe kuMfanekiso 3.

3. Ukulawula ikambiso

(1) Ukumodela: Ngaphambi kokwenza imodeli, sebenzisa isampula ejwayelekileko ye-Φ50×50mm ukuhlola amandla wokucindezela wesihlabathi se-resin ≥ 3.5MPa, bese uqinisa insimbi ebandako nesigijimi ukuqinisekisa bona isikhunta sesihlabathi sinamandla aneleko wokuvala i-graphite ekhiqizwako lokha insimbi encibilikileko nayiqina, ukukhandela ukunwebeka kwekhemikhali yensimbi umgijimi ingcenye isikhathi eside ukubangela isihlabathi ukugeza.

Ukwenza umgogodla: Umgogodla wesihlabathi uhlukaniswe waba ziingcenye ezi-8 ezilinganako ngeembambo ezi-8 eziqinisako, ezihlanganiswe ngomgodi ophakathi. Azikho ezinye iingcenye ezisekelako nezikhiphako ngaphandle kwehloko ephakathi. Nangabe umgogodla wesihlabathi awukghoni ukulungiswa begodu i-Exhaust, ukususwa komgogodla wesihlabathi kanye nemigodi yomoya kuzokuvela ngemva kokuthela. Ngombana indawo yoke ye-sand core yikulu, ihlukaniswe yaba ziingcenye ezisibhozo. Kufanele ibe namandla aneleko nokuqina ukuqinisekisa bona umgogodla wesihlabathi awusoze ulinyazwe ngemva kokukhutjhwa kwesikhunta, begodu awusoze ulinyazwe ngemva kokuthululwa. Ukuguquguquka kwenzeka, ukwenzela ukuqinisekisa ukujiya kweboda elifanako lokuphoswa. Ngebanga lalesi sizathu, senze ithambo elikhethekileko eliqakathekileko, begodu salibophelela ethanjeni lomgogodla ngentambo yokungenisa umoya ukudosa igesi ephuma ekhanda lomgogodla ukuqinisekisa ukuqina kwesikhunta sesihlabathi lokha nasenza umgogodla. Njengombana kutjengisiwe emfanekisweni 4.

(4) Ibhokisi lokuvala: Nakuqalwa bona kubudisi ukuhlanza isihlabathi ngaphakathi komgodi we-butterfly valve, woke umgogodla wesihlabathi upendwa ngamalarha amabili wepende, isendlalelo sokuthoma sifakwe ngepende ye-zirconium ene-alkhoholi (i-Baume degree 45-55), bese kuthi isendlalelo sokuthoma sipendwe begodu sitjhiswe. Ngemva kokomisa, penda isendlalelo sesibili ngepende ye-magnesium ene-alkhoholi (i-Baume degree 35-45) ukukhandela bona ukuphoswa kunganamatheli esihlabathini nokutjhinga, okungeze kwahlanzwa. Ingcenye yekhanda eyinhloko ilengiswe ephayiphini yensimbi ye-Φ200 yesakhiwo esikhulu sethambo lomgogodla ngezikulufu ezintathu ze-M25, ilungiswe begodu ivalwe ngebhokisi lesihlabathi eliphezulu elinama-screw caps begodu ihlolwe bona ukujiya kweboda lengcenye ngayinye kuyafana na.

4. Ikambiso yokuncibilikisa nokuthela

(1) Sebenzisa i-Benxi low-P, S, Ti yekhwalithi ephezulu Q14/16# insimbi yengulube, bese uyifaka ngesilinganiso sama-40%~60%; izinto ezifana ne-P, S, Ti, Cr, Pb, njll. zilawulwa khulu ensimbini elahliweko, begodu akuvunyelwa ukugqwala namafutha, isilinganiso sokungezelela siyi-25%~40%; itjhaji ebuyiselweko kufanele ihlanzwe ngokudubula ngaphambi kokusetjenziswa ukuqinisekisa ukuhlanzeka kwetjhaji.

(2) Ukulawulwa kwengcenye ekulu ngemva kokuvutha: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (okuseleko): 0.035% ~0.05%, ukuvala ngaphasi kwendandatho yendawo, ukuvala, ukuvala kwendawo, ukuvala kwendawo, ukuvala, ukuvala, ukuvala. umkhawulo ongaphasi we-Mg (osele) kufanele uthathwe ngendlela ekungakghoneka ngayo.

(3) Ukwelatjhwa ngokugonywa kwe-spheroidization: kusetjenziswa ama-spheroidizers ane-magnesium encani kanye ne-low-rare-earth, begodu isilinganiso sokungezelela siyi-1.0%~1.2%. Indlela ejayelekileko yokuhlanza ukwelatjhwa kwe-spheroidization, i-0.15% yokugonywa kwesikhathi esisodwa imbozwe ku-nodulizer ezansi kwephakheji, bese i-spheroidization iqediwe. I-slag ibe isivunyelwa ukugonywa kwesibili kwe-0.35%, begodu ukugonywa okugelezako kwe-0.15% kwenziwa ngesikhathi sokuthululwa.

(5) Ikambiso yokuthela msinyana emazingeni womtjhiso aphasi iyamukelwa, amazinga womtjhiso wokuthela angu-1320°C~1340°C, begodu isikhathi sokuthulula singu-70~80s. Insimbi encibilikileko angeze yaphazanyiswa ngesikhathi sokuthululwa, begodu inkomitsho ye-sprue ihlala igcwele ukukhandela igesi nokufaka hlangana ukuthi zingangeni esikhunjeni ngokusebenzisa umgijimi. umgodi.

5. Imiphumela yokuhlolwa kokuphosa

(1) Hlola amandla wokudonsa webhlogo lokuhlola: 485MPa, ukunwebeka: 15%, ubudisi be-Brinell HB187.

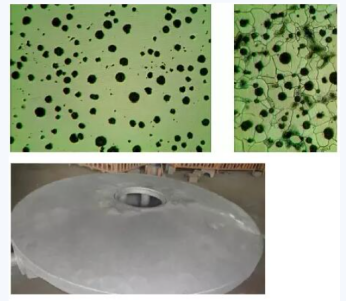

(2) Izinga lokwenza i-spheroidization lingu-95%, ubukhulu be-graphite buyi-grade 6, begodu i-pearlite buyi-35%. Isakhiwo se-metallographic sikhonjiswe kuMfanekiso 5.

(3) Akukho ukukhubazeka okurekhodwako okutholwe ekutholweni kwephutha lesibili le-UT ne-MT yeengcenye eziqakathekileko.

(4) Ukubukeka kuyisicaba begodu kubushelelezi (qala umfanekiso 6), ngaphandle kokukhubazeka kokuphosa okufana nokufakwa kwesihlabathi, ukufakwa kwe-slag, ukuvala okubandayo, njll., ukujiya kweboda kuyafana, begodu ubukhulu buhlangabezana neemfuneko zemidwebo.

(6) 20kg/cm2 ukuhlolwa komfutho wamanzi ngemva kokucubungula akutjengisi ukuvuza

6. Isiphetho

Ngokuya ngobujamo be-velve ye-butterfly, umraro wokungazinzi nokutjhuguluka okulula komgogodla wesihlabathi esikhulu phakathi nokuhlanza isihlabathi okubudisi kurarululwa ngokugandelela ukuklanywa kwehlelo lenqubo, ukukhiqizwa nokulungiswa komgogodla wesihlabathi nokusetjenziswa kweengubo ezisekelwe ku-zirconium. Ukubekwa kweembobo zokukhipha umoya kugwema amathuba wokuba nama-pores ekuphosweni. Kusukela ekulawuleni ukutjhaja kwe-furnace kanye nehlelo lokugijima, isikrini sokuhlunga se-foam ceramic kanye nethekhnoloji ye-ceramic ingate isetjenziselwa ukuqinisekisa ukuhlanzeka kwensimbi encibilikileko. Ngemva kokwelatjhwa okunengi, isakhiwo se-metallographic se-casting nezinye iinhlobo. Ukusebenza okupheleleko kufikelele iimfuneko ezijayelekileko zamakhasimende

KuI-Tianjin Tanggu Water-seal valve Co.,ltd. Ivalvu ye-butterfly, ivalvu yesango, I-Y-strainer, i-wafer dual plate check valveukukhiqiza.

Isikhathi sokuposa: Apr-29-2023