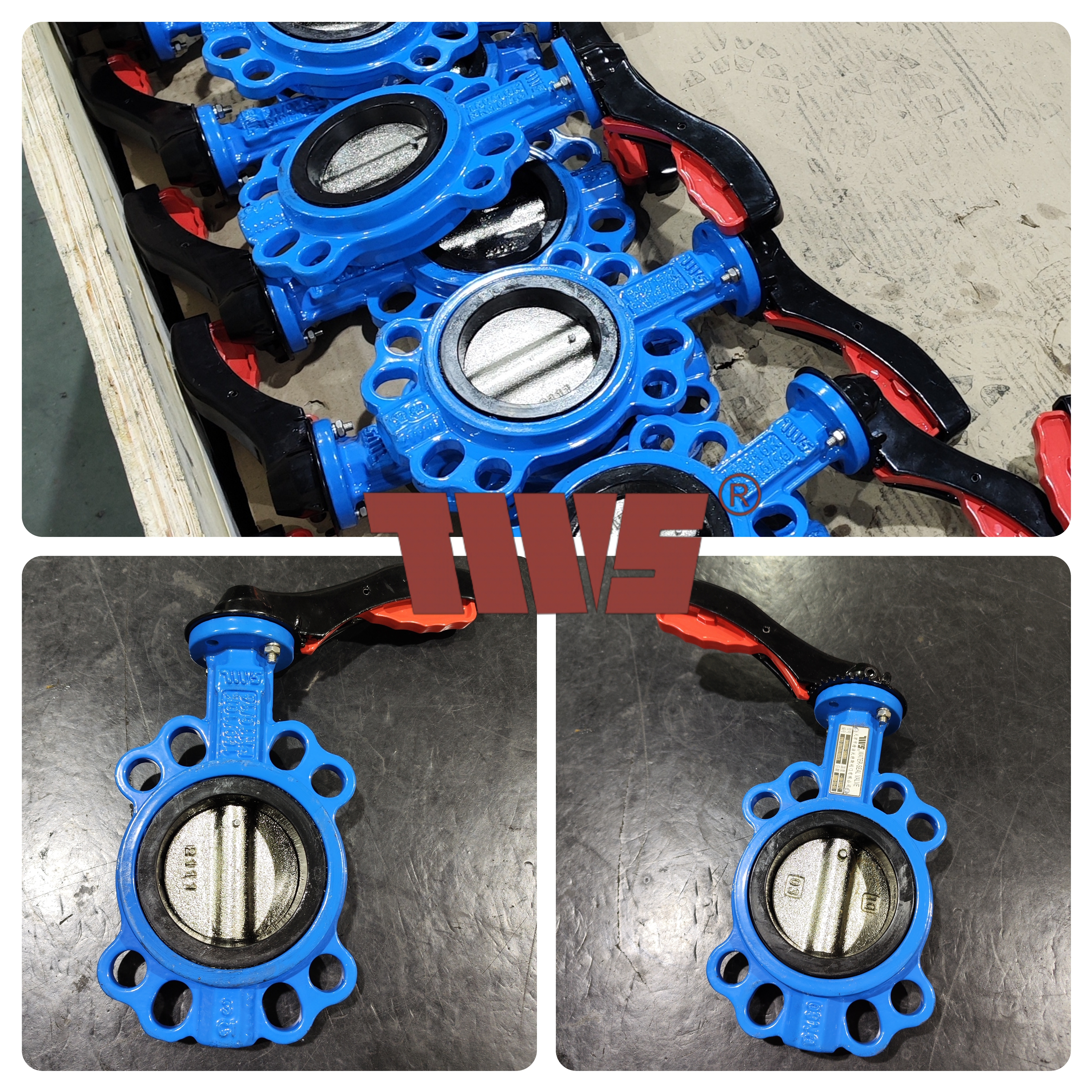

Amavalvu we-butterfly mavalvu asetjenziselwa ukulawula nofana ukuhlukanisa ukugeleza kwamanzi nofana igesi erherhweni lamapayipi. Hlangana nemihlobo ehlukileko yamavalvu we-butterfly emakethe, njenge-wafer butterfly valve,ivalvu ye-lug butterfly, ivivane elineenhluthu ezimbili njalonjalo. Amavalvu we-butterfly avalwe ngerabha abonakala ngokusebenza kwawo okuhle khulu kokuvala nokuthembeka. Esihlokweni lesi, sizokuhlola ubujamo kanye neenzuzo zamavalvu we-butterfly ahlezi ngerabha avela ku-TWS Valve, umkhiqizi owaziwako embonini.

I-TWS Valve mthengisi ohamba phambili wamavalvu wekhwalithi ephezulu nezinto zokusebenza begodu amavalvu wabo we-butterfly ahlezi ngerabha awafani. Ivalvu yenzelwe ukunikela ngokuvala okuqinileko, ukukhandela nanyana ngikuphi ukuvuza nofana ukugeleza emuva erherhweni lamapayipi. Izitulo zerabha zenziwe ngezinto eziqinileko neziqinileko, eziqinisekisa ukuphila isikhathi eside nokusebenza okuthembekileko ngitjho nangaphasi kobujamo obubudisi bokusebenza.

Enye yezinto eziqakathekileko ze-TWS Valveivalvu yevivane ehlezi ngerabhangamandla wayo wokuvala amahle khulu. Isihlalo serabha sivala ngokuqinileko idiski, ukukhandela nanyana ngikuphi ukuvuza lokha ivalvu nayivaliweko. Lokhu kuqakatheke khulu eensetjenzisweni ezitlhoga ukulawulwa okuqondileko kokugeleza kwe-fluid nofana igesi. Ngevalvu le, abasebenzisi bangaqiniseka bona bangafinyelela ukulawulwa kokugeleza okuqondileko ngaphandle kokuvuza okungakafaneli.

Okhunye okuhle kwe-TWS Valve ye-raba ehlezi nge-butterfly valve yi-torque ephasi yokusebenza. Idizayini yevalvu yehlisa ukutjhayisana hlangana kwediski nesihlalo serabha ukwenzela bona kube lula ukusebenza kuhle. I-torque ephasi yokusebenza ayikhuphuli ukusebenza kuhle kwevalvu kwaphela kodwana yehlisa ukuguga kweengcenye zevalvu, ngaleyindlela kwandisa ipilo yokusebenza. Ukungezelela, ivalvu ifakwe ijamo elihlukileko lediski elinciphisa ukujamelana nokugeleza, okuvumela ukugeleza okusebenzako nokungakavinjelwa.

Phezu kwalokho, amavalvu we-TWS Valve ahlezi ngerabha enzelwe bona kube lula ukuwafaka nokuwatlhogomela. Ivalvu itholakala ngobukhulu obuhlukahlukeneko begodu ingalungiswa ukuhlangabezana neemfuneko ezithileko zamapayipi. Ngebanga lokwakhiwa kwayo okulula, ivalvu ingafakwa nofana ikhutjhwe msinya begodu lula, ukonga isikhathi nemizamo. Phezu kwalokho, iinhlalo zerabha zingatjhugululwa lula lokha nazitlhogekako, lokho kuqeda isidingo sokubuyiselwa kwevalvu ngokupheleleko begodu kunciphise isikhathi sokuphumula.

I-TWS Valve iqinisekisa bona amavalvu wayo we-butterfly ahlezi ngerabha ahlangabezana namazinga aphezulu khulu webubulo nakuziwa ekhwalithi nokuqina. Ivalvu le ihlolwa begodu ihlolwa khulu ukuqinisekisa ukusebenza kwayo nokuthembeka kwayo. Ngokuzibophelela kwe-TWS Valve ekhwalithi, amakhasimende angaqiniseka bona i-valve abatjala kiyo izokunikela ukusebenza okuphezulu begodu ijame ukuhlolwa kwesikhathi.

Ngokufingqa, amavalvu we-TWS Valve ahlezi ngerabha ayisisombululo esithembekileko, esisebenzako sokulawula ukugeleza nokuzihlukanisa eenhlelweni zamapayipi. Ivalvu inikela abasebenzisi ukusebenza okuhle nokuthula kwengqondo ngebanga lamandla wayo wokuvala amahle, i-torque ephasi yokusebenza, nobulula bokufaka nokugcina. Kungakhathaliseki bona kusetjenziselwa amabubulo, wezokurhweba nofana wendawo yokuhlala, amavalvu we-TWS Valve ahlezi ngerabha ayikhetho elihle khulu kizo zoke iindingo.

Ngaphandle kwalokho, isiqhema se-TWS Valve esinamava sabonjiniyela nabothekhnikhi sizokuba khona ebhuthini ukunikela iimvakatjhi ngesiyeleliso seengcwethi, isekelo lobuchwepheshe kanye nezisombululo ezenziwe ngokwezifiso. Inkampani izibophelele ekuzwisiseni iimfuneko ezihlukileko zamakhasimende wayo begodu ibanikeze iinsombululo zamavalvu ezenziwe ngokwezifiso ezihlangabezana neendingo zabo ezithileko, ukuqinisekisa ukusebenza okuhle nokuthembeka. Imikhiqizo le ifaka hlanganaivalvu yokulinganisa, i-wafer dual plate check valve, Y-Strainer njalonjalo.

Isikhathi sokuposa: Nov-17-2023